Our Services

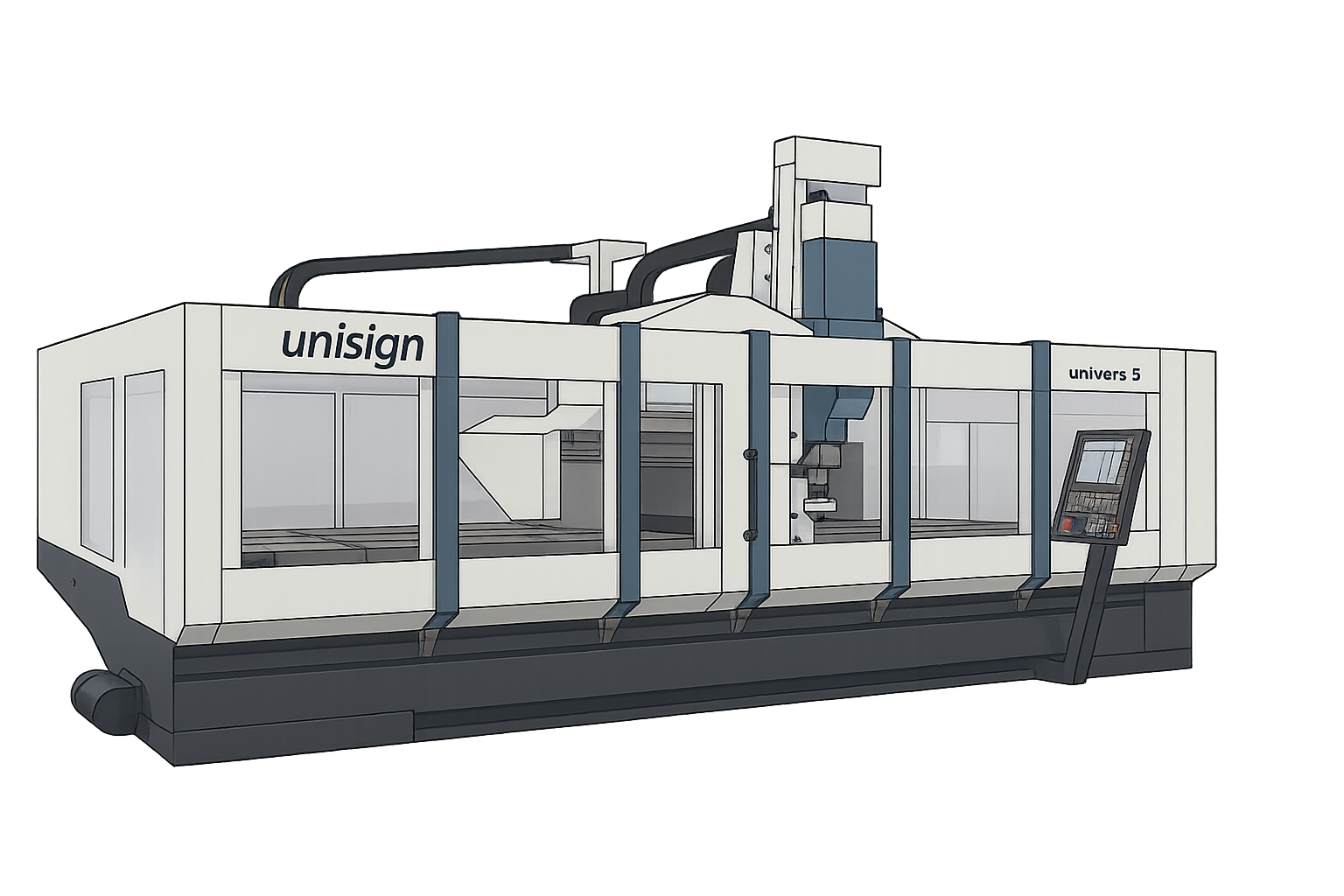

Unisign Univers 5

4‑axis machining center with large capacity Axis travels - X 5000 mm - Y 550 mm - Z 400 mm - B 0° to 360° continuous

Unisign Univers 4

4‑axis machining center Axis travels - X 1600 mm - Y 400 mm - Z 400 mm - B 0° to 360° continuous

Emmegi Satellite XL

5‑axis CNC machining center for aluminium profiles Axis travels - X 6650 mm - Y 760 mm - Z 500 mm - B 0° to 90° continuous - C 0° to 360° continuous

Mazak Integrex 200SY

8‑axis turn‑mill center with Y‑axis - Indexed milling spindle 0.001° - Bar capacity Ø51 mm max - Raw diameter Ø540 mm - Raw length 1000 mm

Spinner SB-CNC

High‑precision lathe Conventional operations - From Ø1 mm to Ø150 mm – max length 1000 mm Swiss‑type / bar work - Bars up to Ø30 mm

Conventional lathe

Manual turning for single parts or repairs Conventional operations - From Ø1 mm to Ø330 mm – max length 1350 mm Gap bed removed - Up to Ø600 mm – max length 130 mm

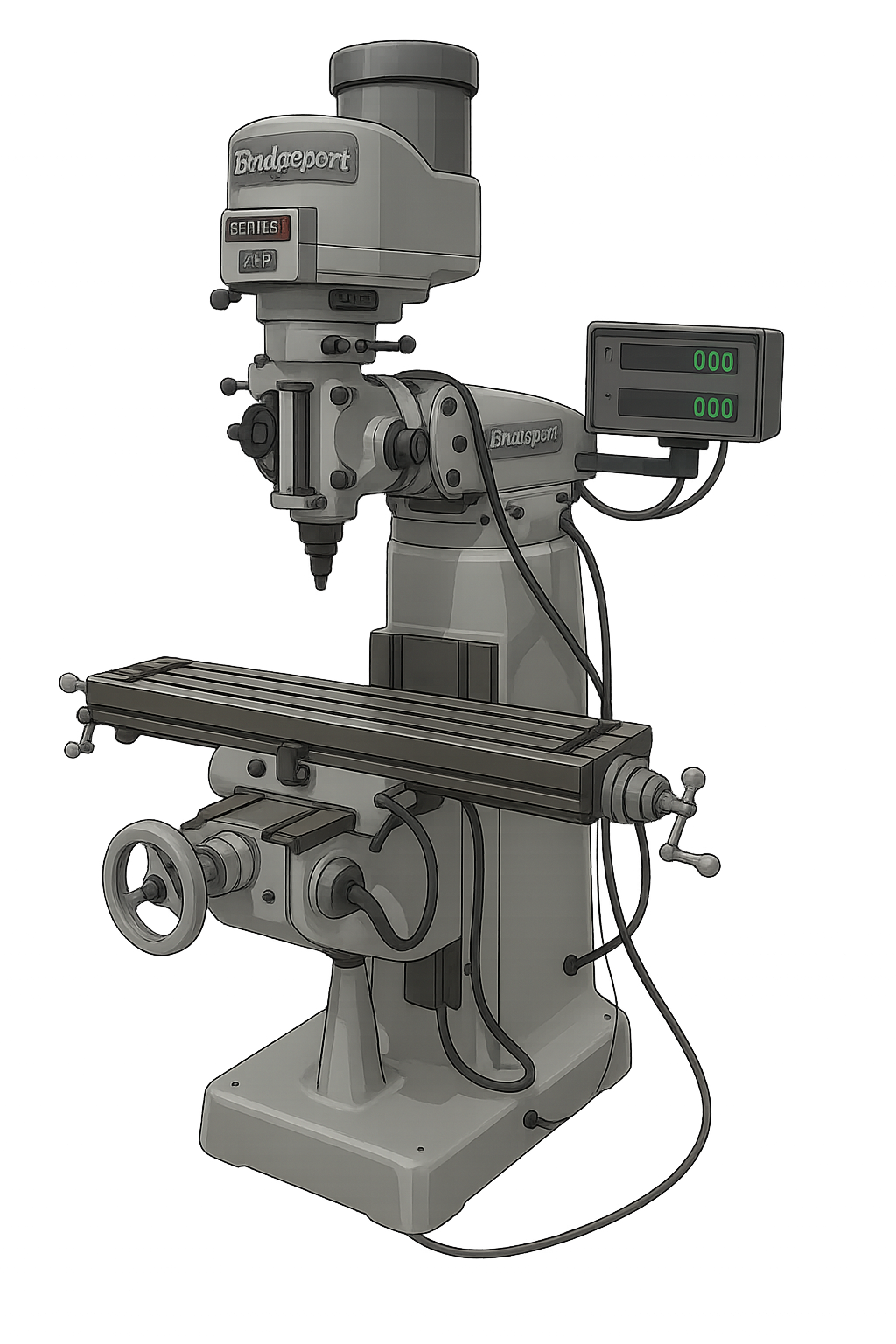

Conventional milling machine

Bridgeport Series 1 - Taper: R8 - Motor: 2 HP – variable speed - Table: 1067 × 229 mm

Surface grinding

Grinding table 152 × 305 mm, wheel Ø203 mm (width 12 mm)

Automatic cutting — Kaltenbach

Two semi‑automatic circular saws Kaltenbach KKS 400 for aluminium cutting, Ø400 mm blades, capacity up to Ø130 mm at 90°

Automated production

6‑axis articulated robot, payload up to 30 kg, reach ~2033 mm

Welding

TIG, MIG, robotic welding — steel, stainless steel, aluminium

Deburring & drying

Vibratory bowl 320 L (Ø1280 mm, width 290 mm), drying unit

Heat treatment

Industrial furnace without controlled atmosphere, up to 1150 °C; quenching, tempering and annealing; volume 500 × 500 × 500 mm

Surface treatment

Glacier Black C7600 — high‑temperature ceramic coating (Cerakote)

Design and simulation

Finite‑element simulation on machined and heat‑treated parts

Prototyping & 3D printing

• FDM printing up to 300 × 300 × 400 mm, fine resolution (XY 0.012 mm, Z 0.1 mm) • SLA 8.9″ 4K screen (3840 × 2400), build volume 192 × 120 × 200 mm, layers 0.01–0.15 mm